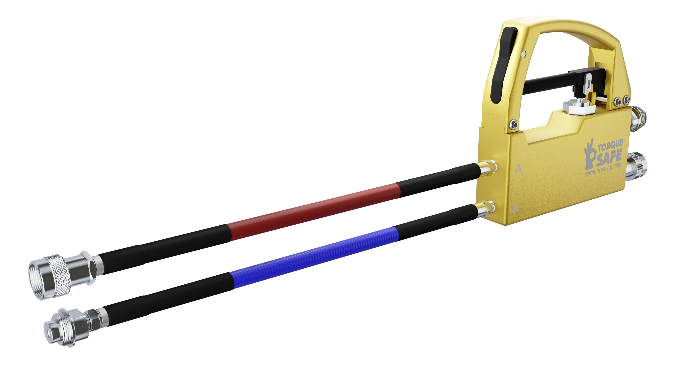

Torque Safe is a patented hydraulic isolation system designed to prevent hand crush accidents caused by hydraulic wrenches.

U.S. Patent No. 10,571,032 and related patents numbers, AU2016214966, CN107250634, EP3254005, and GB2550315

Torque Safe Safety Concern

Hand crush accidents associated with hydraulic wrenches are a serious safety concern. Most accidents happen when one person is actuating the remote and another is handling the tool. Torque Safe isolates the hydraulics and gives control as to when and whether the tool will actuate to the person whose hands are on the tool.

Accidents involving hydraulic torque wrenches are more common than we would like to admit. In fact, if you work with hydraulic torque Wrenches you probably know of someone who has experienced a hand crush accident. Torque Safe engineers the cause of these accidents away by giving the operator control of whether the tool can actuate.

Torque Safe eliminates the problem caused by miscommunication between the operator and the person holding the button. The best way to describe the in-line system is that it functions as a lock-out tag out safety system for hydraulic torque wrenches. It will give the operator a new level of safety that he or she does not enjoy.

Introducing the IN LINE True Dead Man Configuration Torque Safe

With the True Dead Man configuration, the default mode of the system is now Safe Mode. To operate the hydraulic wrench, requires that the tool operator hold the lever up. The instant that he or she lets go of the lever, the system reverts automatically to safe mode.

This feature totally & completely eliminates the chances of an unwanted actuation of the tool.

Additionally, it gives an operator a new safety fail-safe. Should there be unwanted movement such as slippage of the reaction. Simply letting go of the Torque Safe Lever handle stops all tool actuation and allows the operator to safely reset the hydraulic torque Wrench on the application